Although they might not be the first thing that springs to mind when considering equipment maintenance, rubber vibration mounts are essential for maintaining smooth operations and extending the life of your machinery. Selecting the appropriate rubber vibration mounts is crucial for reducing noise, guarding against damage, and improving overall performance—whether you’re working with delicate electronic equipment or robust industrial machinery. In this thorough tutorial, we’ll delve into the world of rubber vibration mounts, examine the various varieties that are available, go over important considerations to make when choosing them, and offer helpful maintenance advice to keep your equipment operating at peak efficiency. Now let’s get going!

Rubber Vibration Mount Types

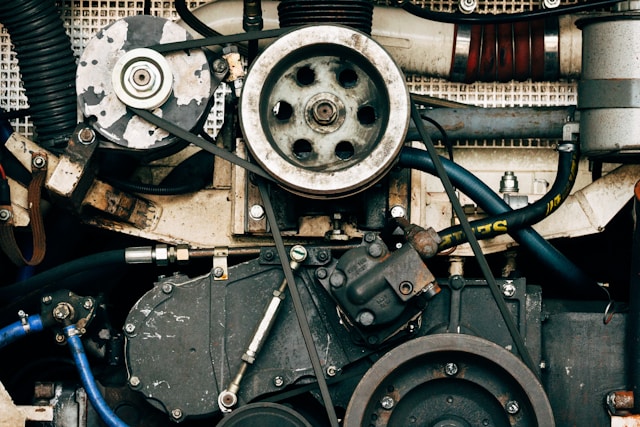

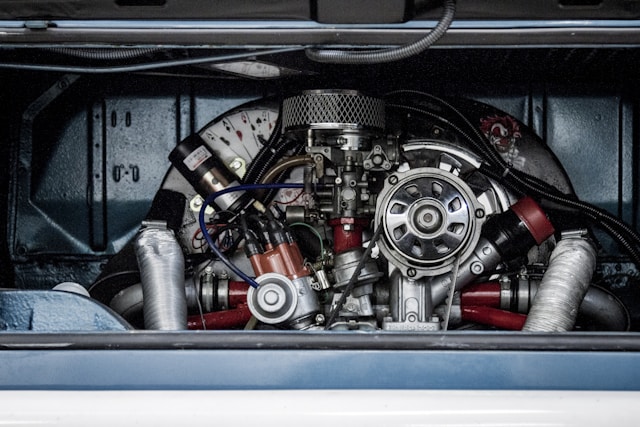

It’s critical to comprehend the various varieties of rubber vibration mounts on the market when selecting the best ones for your machinery. One popular kind is the cylindrical mount, which works well in a variety of applications and is adaptable. To meet your unique demands, these mounts are available in a variety of sizes and load capabilities.

Each form of rubber vibration mounts has its own special features and benefits.

Conical mounts are an additional kind that are renowned for their capacity to reduce vibrations and offer stability. They are perfect for large gear that needs strong support. Popular choices that provide flexibility and shock absorption are pads and bushings.

Additionally, you have the option of using square or rectangular mounts that are intended to disperse weight uniformly and reduce movement while in use. The best rubber vibration mount type will rely on a number of parameters, including load capacity, application requirements, and climatic circumstances.

Considerations for Rubber Vibration Mount Selection

The weight and dimensions of the machinery must be taken into account when choosing rubber vibration mounts for your equipment. To reduce vibrations, the mounts must be able to sustain the weight adequately.

The setting in which the device is used is another important consideration. Select mounts that can withstand hostile environments such as chemicals or extremely high temperatures if it is subjected to them.

Based on whether your equipment generates high-frequency shocks or low-frequency vibrations, think about the kind of vibration isolation that you’ll require. For best results, match the vibration profile of your gear with the appropriate mount rigidity.

Consider the installation specifications as well as the equipment’s compatibility with the mounting locations that are already in place. A good fit will increase the stability and lifespan of the equipment that the mounts support as well as the mounts themselves.

Remember that you have a budget. While purchasing high-quality rubber vibration mounts is key, long-term pleasure depends on striking a balance between price and performance.

Tips for Rubber Vibration Mount Maintenance

Rubber vibration mount lifetime and efficacy depend on proper maintenance. The following are some crucial pointers to assist you maintain the efficiency of your equipment:

- Routine Inspection: Frequently check the mounts for indications of deterioration, wear, or damage. Keep an eye out for any tears, splits, or hardness in the rubber substance.

- Cleaning: To keep the mounts spotless, wipe them down with a mix of water and mild detergent. Steer clear of harsh chemicals since they may deteriorate the rubber.

- Lubrication: To lower friction and increase longevity, some mounts may need to be lubricated. Refer to the manufacturer’s instructions to determine the proper lubricant.

- Temperature Control: To avoid the rubber material ageing too quickly, make sure the surrounding temperature is within the specified range around the mounts.

- Correct Installation: To prevent undue strain on the mounts, adhere to the manufacturer’s recommended installation guidelines.

You can extend the life and performance of your rubber vibration mounts and guarantee the best possible performance from your equipment by carefully adhering to these maintenance recommendations.